Federal Equipment is now a supplier for BLM Group! BLM’s high-end machinery offers tube bending, sawing & turning, and lasertube solutions. Please take a moment to read this blog written by BLM Group on tube bending and how their machines boast capabilities to make the impossible possible…

A COMPACT BENDING HEAD TO PRODUCE NEW GEOMETRIES.

Jul 2, 2021

In the furniture and similar sectors, where the tubes to be bent are often very long and curved into sometimes particularly complex shapes, the bending head must take up as little space as possible to leave room for the shape that the bent tube will assume.

On tube bending machines with right and left-handed bending directions, this need is much less urgent because the possibility of using one or the other bending direction solves many problems of interference between the tube and the other machine parts, but this is not the case on tube bending machines with only one direction of bending. The only way to avoid the risk of interference in the latter case is to reduce the overall dimensions of the bending heads as much as possible.

Precisely to meet these requirements, the BLM GROUP developed a new compact bending head for the ELECT40, capable of executing shapes that were previously not possible with only one bending direction. It is clear that for some parts using a right or left-handed in-process tube bending machine is the only way to be able to produce the parts in a single cycle.

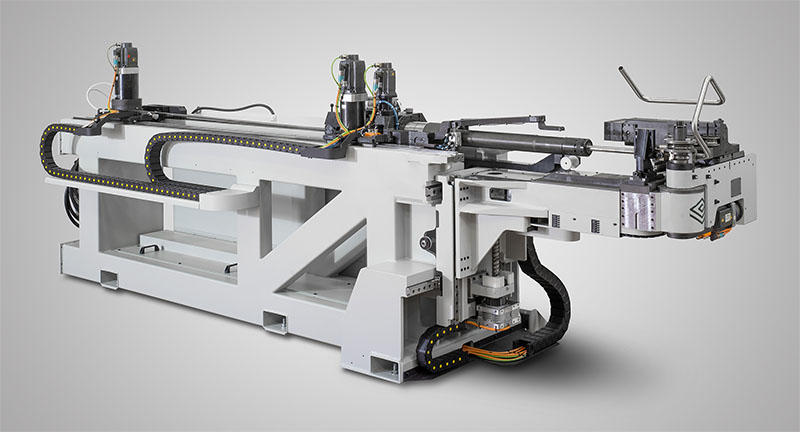

ELECT40 all-electric tube bending with extended bending head.

THE TWO CHARACTERISTICS THAT A TUBE BENDER MUST HAVE TO IMPROVE PART FEASIBILITY.

The fundamental aspects taken into account when designing the tube bending head to deal with geometries that were previously not feasible were:

- reduced height of the bending head;

- greater distance of the bending tool from the machine body.

Reducing the bending head height means that, bend after bend, the tube can move below it. Also, as shown in the figure below, the thinner the head, the more the straight part between the bends can be reduced.

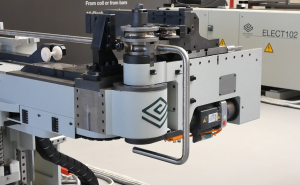

Bending a tube with ELECT40. The small size of the bending head allows the tube to occupy the space below the head.

PRODUCTS REQUIRING A BENDING HEAD WITH MINIMUM DIMENSIONS.

The design of the elongated bending head of the ELECT40 can make all the difference and allow parts to be made that were previously only possible with in-process left and right-handed tube bending machines.

This is firstly an advantage regarding greater parts feasibility, especially for manufacturers who want to approach the furniture sector, for instance, in which tubes must be bent into complicated and overly varied shapes, for manufacturers making tube parts for various types of industrial systems, for the nautical sector (handrails, ladders, etc.) and for farming machinery and equipment.

Designer stool made with ELECT40 tube bending machine with extended bending head.

For manufacturers who already have an in-process right and left-handed tube bending machine, this solution can be an advantage in terms of production organization, by allowing the manufacturer to reserve the most complex parts for the in-process right and left-handed tube bending machine and send parts of medium complexity to the ELECT40 with an extended head.

A solution like this can prove to be a winner, especially for subcontractors who generally have mixed productions in terms of part complexity.

Contact Ron at Federal Equipment to discover more about the new ELECT40. 631-467-9400.